无题

发表于|更新于

|字数总计:2.6k|阅读时长:9分钟|阅读量:

- 0回复

- 收藏

- 点赞

- 分享

- 发新帖

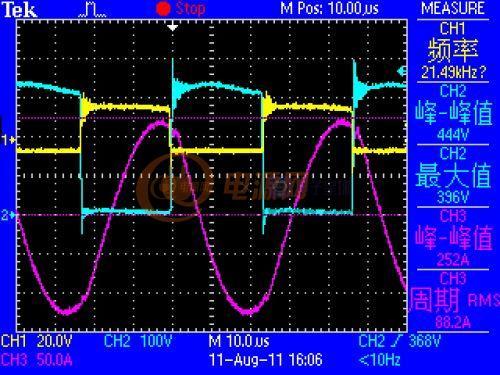

半桥电磁加热,电流和电压的关系

全部回复(41)

正序查看

倒序查看

现在还没有回复呢,说说你的想法

@spt77

空载的Q值怎么只有5.5啊?看来内阻够大的!下面是工作频率21.5k时的计算结果,电源按照直流恒定电压310V来计算的,输出波形仅考虑了基波,谐波忽略。L(uH)C(uF)Q(电感品质系数)工作电压(DC)工作频率(KHz)感抗容抗等效串联阻抗Z谐振频率f0(KHz)负载电流(A,RMS)输入电流(A,RMS)峰值电流(IGBT)KVA (视在功率)相位差(°)KW (有功功率)50.001.882.50310.0021.506.753.942.703.9016.4228.089.9339.713.0846.202.1350.001.883.00310.0021.506.753.942.253.6116.4230.3910.7542.983.3351.372.0850.001.884.00310.0021.506.753.941.693.2816.4233.3711.8047.193.6659.061.8850.001.885.50310.0021.506.753.941.233.0716.4235.6712.6150.443.9166.441.56 我们再看看工作在接近谐振频率时的计算结果:L(uH)C(uF)Q(电感品质系数)工作电压(DC)工作频率(KHz)感抗容抗等效串联阻抗Z谐振频率f0(KHz)负载电流(A,RMS)输入电流(A,RMS)峰值电流(IGBT)KVA (视在功率)相位差(°)KW (有功功率)50.001.882.50310.0017.005.344.982.142.1716.4250.5917.8971.545.549.595.4750.001.883.00310.0017.005.344.981.781.8216.4260.3421.3385.336.6111.466.4850.001.884.00310.0017.005.344.981.341.3816.4279.2428.02112.078.6915.138.3850.001.885.50310.0017.005.344.980.971.0416.42105.8037.41149.6211.6020.3910.87 关键词:串联

0

回复

提示

@spt77

空载的Q值怎么只有5.5啊?看来内阻够大的!下面是工作频率21.5k时的计算结果,电源按照直流恒定电压310V来计算的,输出波形仅考虑了基波,谐波忽略。L(uH)C(uF)Q(电感品质系数)工作电压(DC)工作频率(KHz)感抗容抗等效串联阻抗Z谐振频率f0(KHz)负载电流(A,RMS)输入电流(A,RMS)峰值电流(IGBT)KVA (视在功率)相位差(°)KW (有功功率)50.001.882.50310.0021.506.753.942.703.9016.4228.089.9339.713.0846.202.1350.001.883.00310.0021.506.753.942.253.6116.4230.3910.7542.983.3351.372.0850.001.884.00310.0021.506.753.941.693.2816.4233.3711.8047.193.6659.061.8850.001.885.50310.0021.506.753.941.233.0716.4235.6712.6150.443.9166.441.56 我们再看看工作在接近谐振频率时的计算结果:L(uH)C(uF)Q(电感品质系数)工作电压(DC)工作频率(KHz)感抗容抗等效串联阻抗Z谐振频率f0(KHz)负载电流(A,RMS)输入电流(A,RMS)峰值电流(IGBT)KVA (视在功率)相位差(°)KW (有功功率)50.001.882.50310.0017.005.344.982.142.1716.4250.5917.8971.545.549.595.4750.001.883.00310.0017.005.344.981.781.8216.4260.3421.3385.336.6111.466.4850.001.884.00310.0017.005.344.981.341.3816.4279.2428.02112.078.6915.138.3850.001.885.50310.0017.005.344.980.971.0416.42105.8037.41149.6211.6020.3910.87 关键词:串联

方便给一下里面各参数的计算公式吗,这两天发现半桥工作5.5KW时,线圈中的峰值电流很大,整机工作30多分钟(上下臂的IGBT是H30R120各2颗并联,当时壳体的温度是55℃),IGBT就全部挂掉了,坏的时候是全军覆没,惨呀

0

回复

提示

@happylee

方便给一下里面各参数的计算公式吗,这两天发现半桥工作5.5KW时,线圈中的峰值电流很大,整机工作30多分钟(上下臂的IGBT是H30R120各2颗并联,当时壳体的温度是55℃),IGBT就全部挂掉了,坏的时候是全军覆没,惨呀关键词:半桥 电流 IGBT 并联

没有计算公式,根据成熟产品的一台机子,按电工学基本原理可推算出你要的实际机子的匹配,再加上实际的修正一次,有时更本无须修正。例如根据380V/8KW半桥的线圈,直接推算出380V/20KW全桥三门蒸柜的线圈,并且是一次成功到最佳匹配状态。

你的4只单管做半桥已是满额使用,没有电流富裕量,保护稍有不对或工作状况不佳的话,烧管的概率是很大的。

关键词:全桥

0

回复

提示

@spt77

空载的Q值怎么只有5.5啊?看来内阻够大的!下面是工作频率21.5k时的计算结果,电源按照直流恒定电压310V来计算的,输出波形仅考虑了基波,谐波忽略。L(uH)C(uF)Q(电感品质系数)工作电压(DC)工作频率(KHz)感抗容抗等效串联阻抗Z谐振频率f0(KHz)负载电流(A,RMS)输入电流(A,RMS)峰值电流(IGBT)KVA (视在功率)相位差(°)KW (有功功率)50.001.882.50310.0021.506.753.942.703.9016.4228.089.9339.713.0846.202.1350.001.883.00310.0021.506.753.942.253.6116.4230.3910.7542.983.3351.372.0850.001.884.00310.0021.506.753.941.693.2816.4233.3711.8047.193.6659.061.8850.001.885.50310.0021.506.753.941.233.0716.4235.6712.6150.443.9166.441.56 我们再看看工作在接近谐振频率时的计算结果:L(uH)C(uF)Q(电感品质系数)工作电压(DC)工作频率(KHz)感抗容抗等效串联阻抗Z谐振频率f0(KHz)负载电流(A,RMS)输入电流(A,RMS)峰值电流(IGBT)KVA (视在功率)相位差(°)KW (有功功率)50.001.882.50310.0017.005.344.982.142.1716.4250.5917.8971.545.549.595.4750.001.883.00310.0017.005.344.981.781.8216.4260.3421.3385.336.6111.466.4850.001.884.00310.0017.005.344.981.341.3816.4279.2428.02112.078.6915.138.3850.001.885.50310.0017.005.344.980.971.0416.42105.8037.41149.6211.6020.3910.87 关键词:串联

你好,我是新接触电磁加热的 ,咱们这个Q值是怎么计算的,谢谢指教!

0

回复

提示

立

即

发

帖

文章作者: ZhaoYichen

版权声明: 本博客所有文章除特别声明外,均采用 CC BY-NC-SA 4.0 许可协议。转载请注明来自 赵逸尘个人博客!

公告

This is my Blog